PAVE offers many technical answers to frequently asked questions about installation, designs, leak rates, and more

1. PAVE-Seal® and PAVE-Mate® Installation Instructions

NPT PAVE-Seals: It is recommended that pipe threads be tightened 2 1/2 full turns past finger tight unless otherwise noted on PAVE drawings. PTFE tape or another thread sealant should be used. “As a general rule, fittings with tapered pipe threads (NPT) should not be assembled to a specific torque because the torque required for a reliable joint varies with thread quality, port and fitting materials, sealant used, and other factors” Parker Hannifin Catalog 4300 Port End Assembly, page T7. – View

Straight Thread PAVE-Seals (SO Type): Parker Hannifin Corp. tapping and counter-boring tools are recommended for proper port drilling. Please order these tools through your local Parker distributor. Tighten to 20 Ft. Lbs (27 Newton-Metre). Do not use PTFE tape on SO thread-type penetrations.

Jam Nut/O-Ring (VS Type): The bulkhead surface sealing to the o-ring must be smooth (32 RMS finish or better), flat, and perpendicular to the axis of the threads. The jam nuts should be tightened snug using 12 to 20Ft. Lbs. of maximum force (16-27 Newton-Metre). Excessive force is unnecessary and may damage the seal. The thruhole diameter should be the thread size or thruhole I.D. +.010″,-.000″ (+0,254mm, -0,000mm).

The preferred installation has the O-ring on the pressure or atmosphere side. The PAVE-Seal can also be installed into a tapped port without the jam nut. However, a small counter-bore in the bulkhead is may still be required on the o-ring side to properly seat the o-ring since there may not be a thread undercut in the VS housing.

Conflat® Type PAVE-Seals (CF Type): Available with either fluorocarbon (Viton) or OFHC copper gaskets, the maximum torque required to seal the flange is 16FT. Lbs(22 N-M)

Molded Epoxy piston o-ring PAVE-Seals: Port should be designed per standard o-ring handbook specifications for the appropriate o-ring size with proper 15 º lead-in, compression (usually 30%) and finish (32 RMS or better). Molded PAVE-Seal o-ring groove will have been properly de-flashed. Approved installation port dimensions are either in catalog or on PAVE drawing. If not sure of port dimensions, please ask for PAVE Sales Engineering assistance.

View the PAVE-Seal Non-threaded Piston O-ring installation Animation

High-Pressure Use: High (over 500 psi, 30 bar) or bi-directional pressures and/or temperatures sometimes require special design installation considerations. See PAVE drawings. PTN Hex Nipple PAVE-Seals which are to be subjected to these conditions are identified by a blue/black band encircling one thread end of the PAVE-Seal. The blue/black band indicates the high-pressure end to which the extreme atmosphere is to be applied. High-pressure ratings are not normally bi-directional. The high-pressure side is normally the hex side (o-ring to be pushed into bulkhead) or thread side (NPT). The customer should clearly indicate pressure direction at the time of order to avoid improper installation and seal performance. Contact factory sales engineering before using in long-term steam. No warranty for steam service exists without special certification from the factory.

O-rings should always be properly lubricated with a thin film of o-ring grease. The O-ring on PAVE housings may be dry if no lubricant is noted on the drawing or may be lubricated at the factory with Fomblin VAC 3 for low outgassing in high vacuums or Parker O-Lube grease or otherwise noted on PAVE drawings. Dry non-lubricated o-rings can be requested if preferred and leak tested with IPA that evaporates quickly.

DSUB Rectangular connectors should be installed with a torque on their screws tightened to 4-5 inch-pounds or 0.45 newton meters.

IF A PROBLEM DEVELOPS, PLEASE CONTACT THE FACTORY QA Department (1-937-890-1100 x24) OR YOUR LOCAL SALES REP IMMEDIATELY. While very unusual, most leaks are due to either improper installation or thermal shocking the unit beyond its rated temperature. Our goal is to keep all of our customer satisfied, so let us know how we can help.

2. Does the PAVE-Seal versions with insulated and stranded conductors have a much higher leak rate compared to the PAVE-Mate styles with solid pins?

No. There is no difference whether the conductors are insulated wires or cables or pins. All wiring is specially sealed and processed to prevent any significant or detectable leakage through the wire or cables, including any shielding. This applies whether the requirements involve gas, fluids (oils, solvents, fuels, saltwater, freons, etc), vacuum, low or no pressure water vapor or high pressures of 30 to +1000 bar.

3. What are the available circular connector contact or pin arrangements available as PAVE-Mate connectors that connect to MIL-Spec or commercial connectors?

View the available circular connector contact or pin arrangements that connect to MIL-Spec or commercial connectors.

4. Where can I find the PAVE-Mate connector pin and wire assembly instructions?

5. Can the customer order additional mating plugs or contacts for the PAVE-Mate series?

Yes. Contact help@pavetechnologyco.com for the proper part number.

6. Do you have other PAVE-Mate connector pin arrangements not shown in the catalog, as well as all the contact arrangements lettering or numbering?

Yes, we only show a partial listing and can make hermetic versions of any commercial or military connector series, including coaxial, thermocouple and fiber optic versions. Please contact Sales Engineering for more information.

For Contact insert pin out lettering or number identifications, please click on the appropriate link below.

For PAVE-Mate Type 3112 bayonet disconnects based on MIL-C-26482 pin arrangements

For PAVE-MATE Type 3102 threaded coupling disconnects based on MIL-C5015 pin arrangements

For PAVE-MATE Type 27466, 27508, 99920, 99940 bayonet, threaded or push-pull disconnects based on MIL-C-38999 Series 1, 2, 3, or 4

7. How do I find out what is available in existing PAVE designs?

First, review our catalog, Product Index, or In-Stock Price List for ideas and examples. We offer standard, semi-custom and custom seals in three basic styles with almost unlimited variations.

The first style is the PAVE-Seal Harness with insulated wires on both sides of the bulkhead.

The second style is the PAVE-Mate I that has a connector on both sides of the bulkhead.

The third basic style is the PAVE-Mate II that is a combination of the first two styles with a connector on one side and insulated wires (or solder cup pins) on the other side. We do have other assemblies not displayed that do not have complete drawings as well, which Sales Engineering can explain their availability upon request.

Our standard designs are in the catalog section, listed in our In-Stock Price List or Product Index section.

We have many other standard designs not displayed that we can offer once we are made aware of your minimum requirements using our Quotation Request Forms on pages 7, 14 or 23 in the catalog that we attempt to match up with existing products. Tell us your minimum electrical requirements as to the number of conductors, the minimum size of the conductor (amperage), and voltage. Then also indicate your minimum critical mechanical requirements such as the available bulkhead or wall thickness, maximum outside diameter or space available and method of installation. Thin wall bulkheads of less than 3/8″ (0,9mm) will usually limit housing choices to using a jam nut, bolted on the flange or a welded housing. Please use our quote forms to include other critical operating specifications such as pressure, the vacuum or pressure’s direction (especially needed for +30 bar pressure seals) and temperature operating range.

Our semi-custom designs allow the customer to specify unique combinations of standard housings, wire and/or pins shown in our catalog. Our sales engineering will quickly confirm that the unique combination is a valid design. We offer basic design guidelines such as minimum wire or conductor spacing on page 7 in our catalog (see question six that follows in this section). However, there can be so many variables and exceptions due to pressure, temperature, voltages, etc. that we do not try of address all these issues online. Send your request and we will quickly confirm the design or we will make recommendations.

Our custom designs allow the customer to use his imagination to specify a solution to his seal requirements. We will work closely with the customer to produce a high quality and cost-effective design and final product. Again, use our quote forms as a guideline and send us whatever type of concept drawing you may have for our review. If you have no drawings, explain the problem, including operating conditions and your objective. Our quote form in the Design Assistance section or on page 23 of the catalog can be a useful guideline for the customer in providing us the necessary information. Include any price range you are attempting to meet, so we can direct you to a proper design, particularly for large quantities. You can also e-mail CAD drawings compatible with AutoCad Lite or 14 in a .dxf or .dwg file format to attention Contact us

8. How does PAVE seal PTFE, stranded, shielded wire?

The exact process is proprietary, but we can seal virtually any type of wire or cable. In addition, the wires can be cut to any length or handled as any other cable without affecting the seal integrity or leak rate.

9. How are the minimum seal length and the minimum outside diameter of the seal determined?

The minimum seal length is a function of the pressure differential, leak rate, conductor dimensions, voltage and operating temperature range. Most seal lengths are from 0.30 inch (7,7mm) to 1 inch (25mm) or more. Longer seal lengths typically have higher pressure ratings. Seal thickness can be as small as 0.100 inches or less for low pressure (less than 10 bar) or ambient temperature (80º C maximum).

1000 bar will require a 25mm length or more. In order to bond properly to wire insulation, we recommend lengths typically between 12 and 25 mm where possible, though seals as thin as 0.100 inches may be available for low pressure and ambient temperature applications.

The outside diameter of the seal is determined by the number and size of conductors, any electrical shielding, whether the housing is metal or plastic and the size and type of the o-ring seal if an O-ring is used. Small wires sizes of #22 AWG (0,78mm) or smaller can be spaced on 0.050 inches (1,3mm) centers. Larger wire conductors will require wider spacing for both electrical and mechanical reliability from 2-3 mm or more.

High pressures of over 30 bar, temperatures between over 80º C up to 200º C or voltages over 1000 Vac may also require slightly more spacing. Electrical shielding (sheathing) or braid will also increase the seal diameter, especially if the shielding is to be carried through the seal. Essentially, the shield will take up the same space as a ring of individual wires around the center wire.

10. Where can I get help on retaining or snap ring design and usage?

You can find retaining or snap ring design help and assembly tools at www.smalley.com (stainless steel high-pressure versions are also available) or www.rotorclip.com or www.truarccorp.com.

View the PAVE-Seal Non-threaded Piston O-ring Installation Animation

For Standard Ring Series Selector Guide, click here.

11. Where can I find sources for available cables and their specifications that PAVE can seal?

See www.belden.com or www.astro-ind.com for starters. For thermocouple wire, see www.pmcwire.com or www.omega.com. Other sources are available depending upon cable or wire requirements. Please contact PAVE Sales Engineering for help.

12. Do you supply PAVE-Seal Wire Harnesses with the wire ends terminated with connectors?

Upon request, PAVE can supply any type of wire connector termination as specified by the customer. This value-added service allows the customer to simply install our seal directly to his system with all termination’s supplied. This value-added service is usually limited to production applications of 100 or more assemblies, though any quantity will be quoted if so requested. We have a wide range of AMP, Molex, Deutsch, and other crimping machines.

13. Does the customer have to go through the local sales representative? Or can the customer contact PAVE Sales Engineering or place a Purchase Order directly to the Dayton, Ohio USA location?

Yes, customers are always welcome to contact PAVE Sales Engineering directly if they prefer. Contact PAVE via telephone (+1.937.890.1100 x103, enter extension 6 or 14 upon hearing our recorded welcome), fax (+1.937.890.5165), email Sales, overnight courier, personal visit or mail to our address at the bottom of our web site welcome page. Our local sales representatives can be very effective in following up on any unresolved issues.

We encourage the customer to use our local representatives, if one is available for the customer’s area, that may also be able to show the customer samples. PAVE sales representatives are listed on this Web site for those areas that have a sales representative. It is not required by PAVE for the customer to contact our local sales representative. PAVE will inform the local PAVE sales representative of any customer contact. All purchase orders must be written and confirmed via fax or mail directly to PAVE Technology Co®. at the Dayton, Ohio USA location prior to shipment. This is required even if the purchase order is initially placed through the local sales representative. MasterCard and Visa credit card orders are also accepted at PAVE.

14. I only need a very small quantity. How do I find our what PAVE stocks?

First, check our In-Stock Price List. The products listed for quick delivery are in stock for immediate delivery for relatively small quantities and is updated quarterly. If you do not find anything on the posted price list, please call our main number at 1 937 890 1100 x0 to check for any other stock product updates. Please refer to our description code at the end of the price list to be able to understand the product codes on the price list. Call for any assistance or updates.

In addition, we will quote all quantities. Delivery can run from 1 week to 3 months, depending upon the design. Pricing is based on the design and quantities. We also can usually offer faster delivery with premium pricing, if the customer requires quicker delivery.

15. What type of leak rates are possible?

Almost all of the leak rates of our products fall between 1 x 10-6cc/sec to 1 x10-9cc/sec at 1 atmosphere (1 bar) pressure differential. PAVE products are capable of helium leak rates in the 10^-9cc/sec even at high pressures of 6,000 psi (400 bar) using multiple )-rings and various types of wires or pins! The actual calibrated leak rate will vary due to size and type of housing, number of wires or pins and the actual pressure differential.

Though the leak rates are very low, we have a very wide range of products to fit the customer’s budget and performance requirements based on the materials specified and the quantities ordered. We serve a wide range of customer types from very small pressure requirements to customers with very high pressures or vacuums. We perform low-cost nitrogen bubble leak test at 5 bar, calibrated helium leak testing or high-pressure nitrogen bubble leak testing to 600 bar or more. We can do either 100% or sampling based on quality assurance standards. Even a very small pressure differential of only 1 psi can create significant problems if the leak rate must be very small or essentially non-detectable.

We also make explosion-proof (Exd, UL, CSA, or FM) seals or lower cost “environmental” seals if sealing only to the cable jacket is required with no seal to the inner conductor required. The customer specified leak test procedure will help determine how rigorous or hermetic the seal must be. We can offer guidance as necessary in helping define an appropriate leak test procedure so the customer gets the quality seal he needs. It is difficult to always correlate a helium leak rate test to a moisture-proof leak rate.

For additional information see: ACCP Level II Certification

16. Can the customer supply PAVE their cable or connector to be sealed?

Yes, we can work with any cable. PAVE normally supplies all material, but if special customer cable needs to be used, we can seal it.

17. I do not need a hermetic seal, only environmental seal. Can PAVE provide a lower cost seal solution?

In most cases, we have more than one level of seal quality if a customer has reduced seal requirements. The level of seal is determined by defining a proper leak test procedure so we know we are in compliance with the customer’s expectations. Once defined, we can quote accordingly.

18. How do I order a fiber optic seal?

PAVE can seal a wide range of fiber optic cables or supply quick disconnect PAVE-Mate versions. Seals using fiber optic cables are usually special order. Some standard PAVE-Mate connector designs are shown in the Design Library Annex in the Fiber Optic section. Normally, the customer will supply the fiber optic cable where we are sealing small quantity cables into one of our either standard or custom housings. We can work with either single or multi-mode cables.

Fill out a quote request form as completely as possible and include a detailed specification of the cable showing its construction. Any special requirements for polishing or maximum microbending must also be stated. The easiest fiber optic cable for us to seal is bare cable (we can add a PTFE jacket) or multi-mode. The most difficult are those cables requiring special processes to strip off the cladding and buffer or single mode cables. Our sealing creates almost no attenuation, whether the application is high vacuum or high pressures. If terminations are required on the cable, the following PAVE-Mate requirements also apply.

If a PAVE-Mate style fiber optic cable is desired such as ST, SMA, etc, it is important that the mating connector plugs and couplers/adapters are clearly identified with the manufacturer and part number. For small quantities, it may be required that the customer supply such parts. It would also be important for the customer supply test patch cords for use with our 850nm and 1350nm light sources for testing the finished PAVE-Mate prior to shipment to the customer. Alternate test methods such as UV-visible light may also be available. Multi-mode fiber optic cable is standard. Single-mode versions have much more limited availability and much higher costs.

Please send a sample of your fiber optic cable for our evaluation.

19. Does PAVE have an automotive quality report on PAVE products used on the 1995-97 Ford Explorer SUV in the electronic stability control suspension system?

20. Does PAVE have any test data from a recognized laboratory, such as NASA, that demonstrates that PAVE epoxy sealants have very low vacuum outgassing characteristics?

21. What does the -E- mean versus the -SS- description for the PAVE-Mate I connectors?

The -E- in the PAVE-Mate I description refers to the hex area being molded epoxy that includes the o-ring groove, while the threads and jam nut are still metal 300 series stainless steel and the connector shells are nickel-plated aluminum.

There is no difference in performance between the -SS- or -E- versions, only a slightly higher price for the -SS- VS housing, where available. Slightly more care should be followed per the installation instructions for the -E- versions, so parts are not overtightened, which is unnecessary and could cause damage.

22. Where can I find technical help on o-rings?

« Typical Fluorocarbon/Viton o-ring specification used with PAVE seals —View

« Parker O-Ring Handbook Parker O-Ring Division.

PAVE can supply the o-rings dry without any o-ring grease. Or supplied with Parker Super O-Lube (200C silicone based) or Parker O-Lube grease (barium) or Fomblin Vac 3 high vacuum grease. O-ring grease normally used is so noted on the particular part # drawings.

23. Does PAVE offer welded junctions on its thermocouple hermetic wire seal products?

For an additional charge, PAVE offers welded accurate junctions on standard thermocouple wire on its hermetic seal products. The junctions can be formed as ordinary freestanding beads, welded to attachment hardware like nuts, bolts and washers or joined directly to the metal parts being sensed.

Contact your PAVE Sales Engineer for pricing.

24. Do you have any current quality reports showing the strong performance, reliability and high quality of PAVE-Seals in large production volumes?

25. Are PAVE products bi-directional seals?

Yes, PAVE products seal bi-directionally for most vacuums and low to moderate pressure seals typically up to 20 bar (300 psi). For higher pressures, confirm proper installation and pressure direction with factory sales engineers, as most seals have much higher pressure ratings available, but usually restricted to a certain pressure direction only.

26. How do I determine amperage or current load capacity of a given size wire conductor or copper rod?

Current capacity is affected by many different factors, including how much heat is carried away from the conductor. This would be theoretically more limited if there is less air surrounding the conductor (lower pressure), but a curve showing this would have to be generated with a specifically controlled experiment in the actual customer’s application. The current capacity has no relation to the pressure or vacuum level. The only direct relation that the pressure or vacuum level has to an electrical characteristic is the voltage rating. However, we don’t have any data to develop a curve that shows that relationship.

See weblink https://www.powerstream.com/Wire_Size.htm for more information on amperage load carrying capacities and AWG wire sizes and metric wire gauges.

Refer to this diagram to view our recommendations for copper wire conductor gage or size or solid connector contact or pin sizes (AWG or mm diameter) based on the maximum amperage load or its duty cycle.

27. Besides meeting low emissions standards for small engine technology such as motorcycles what large engine applications use PAVE seals?

28. Are your wire seals and connectors compliant to RoHS specifications?

All our wire seals and connectors either are already RoHS compliant or can quickly be made compliant to RoHS standards upon request.

29. Does PAVE offer special cleanliness and packaging processes to further reduce any high vacuum outgassing?

Yes, upon request for many of our semiconductor customers, we typically vacuum bake PAVE hermetic seals up to 10^-6 Torr @121C for several hours and then special package. All this special processing is done within a Class 100 laminar flow hood environment.

PAVE can supply the o-rings dry without any Parker Super O-Lube or barium base Parker O-Lube grease. Most of our products using face-seal o-rings are dry and if an o-ring grease is used on the face seal O-ring, it is so noted on the drawing, otherwise, if no grease is noted on the drawing the face seal O-ring is dry.

PAVE recommends Apiezon T high vacuum grease for most high vacuum systems where silicone based grease is not acceptable. Where the customer has very sensitive outgassing requirements, please check with the PAVE sales engineer to further assure the proper cleanliness is met by our product for your requirements.

30. Does PAVE offer special for high vacuum low outgassing connectors in its dual-sided PAVE-Mate I connector line?

Yes. PAVE-Mate I 1637-1 (26 #20 AWG) and 1897 (6#20 AWG) have very low outgassing high vacuum Viton or epoxy insert female socket receptacles and mating male pin plugs. Other contact arrangements with these materials can also be supplied upon request.

PAVE can supply the o-rings dry without any Parker Super O-Lube or barium base Parker O-Lube grease. Most of our products using face-seal o-rings are dry and if an o-ring grease is used on the face seal O-ring, it is so noted on the drawing, otherwise, if no grease is noted on the drawing the face seal O-ring is dry.

PAVE recommends Apiezon T high vacuum grease for most high vacuum systems where silicone based grease is not acceptable. Where the customer has very sensitive outgassing requirements, please check with the PAVE sales engineer to further assure the proper cleanliness is met by our product for your requirements.

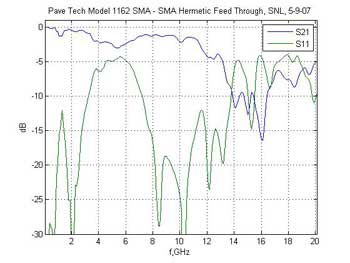

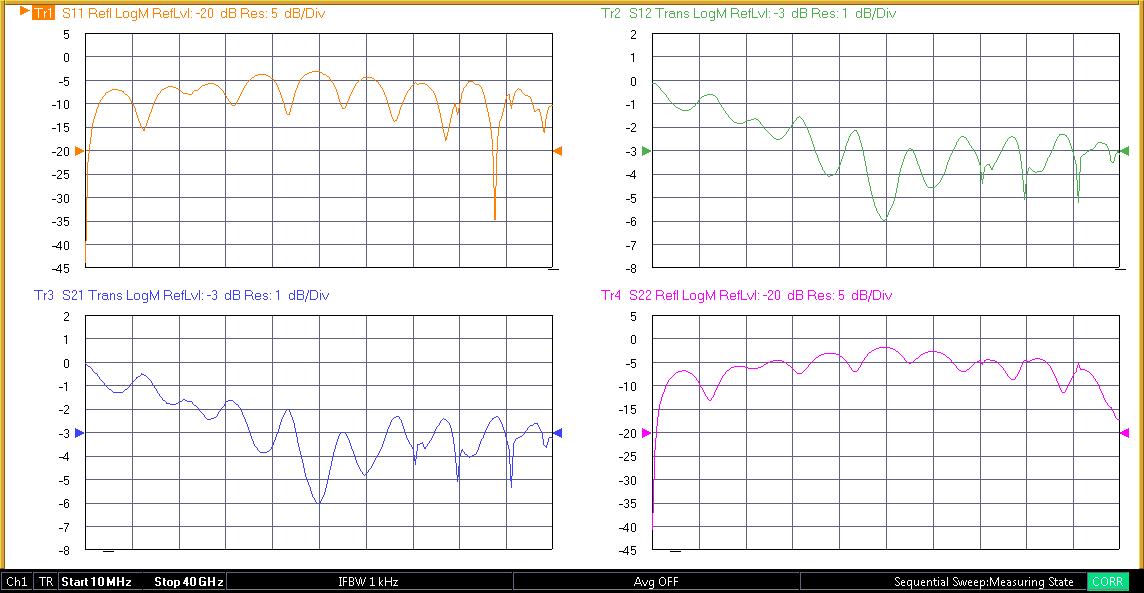

31. Does PAVE have electrical test data on your SMA frequency characteristics?

Please see the below chart of the plot of transmission and reflection coefficient that measured the full 2-port S-parameter data on a Sandia National Lab network analyzer

Download Serno 336851-033 Data

Download PAVE-MateR 4708 Data

32. Can PAVE supply the o-rings used on their products used without any silicone O-ring grease or lubricant material that might contaminate a high vacuum system sensitive to silicone?

PAVE can supply the o-rings dry without any Parker Super O-Lube or barium base Parker O-Lube grease. Most of our products using face-seal o-rings are dry and if an o-ring grease is used on the face seal O-ring, it is so noted on the drawing, otherwise, if no grease is noted on the drawing the face seal O-ring is dry.

PAVE recommends Fomblin YVAC 3 or Apiezon T high vacuum grease for most high vacuum systems where silicone based grease is not acceptable. Where the customer has very sensitive outgassing requirements, please check with the PAVE sales engineer to further assure the proper cleanliness is met by our product for your requirements.

33. What is the wire pull test specs?

The wires are permanently and very strongly bonded in the epoxy seal such that the copper conductor tensile strength will almost always be exceeded causing the wire to break before it can be pulled out of the epoxy seal.

34. Do PAVE-Seal wire harnesses seal to very low -100C or near cryogenic temperatures such as with LNG?

While PAVE cannot verify or test the use of our seals at such low temperatures, many PAVE customers have used our products successfully for very low temperatures when the standard o-ring compound (typically Viton) is replaced with a Teflon PTFE o-ring rated to -100C to 260C. These o-rings can be ordered at www.mcmaster.com or others. If the epoxy seal is in a metal housing instead of molded epoxy housing, the customer should special order the wire seal indicating the low-temperature use expected, though the most PAVE will likely warranty is to -100C use. We appreciate your feedback on your usage of our products as well.

35. Does PAVE have any rigorous life cycle testing on its epoxy molded wire seals?

PAVE-Seals have passed very rigorous automotive life cycle tests in diesel fuel and oil of 20 million cyclic pressure and temperature tests between -40 to 170C between 0- 1000 psi (and to 2500 psi) with no failures whatsoever! From this testing and results, a service life of 600 million pressure cycles or 20,000 service hours @500 CPM is projected.

These special tooled seals also comply to UL94V-O flame rating specification with a much higher relative thermal index (RTI) value of 130C compared to 90C for our standard seals. In addition, PAVE can add an optional tight tolerance machined metal sleeve to our low cost molded epoxy o-ring seal housing designs that would comply to the maximum flame path gap clearance required for UL or ATEX explosion-proof seals.

36. Does the PAVE-Seal epoxy resist strong solvents, acids, and other chemicals?

While PAVE does not do any chemical resistance testing, PAVE hermetic epoxy seal feedthru connectors have been used by our customers for many years successfully sealing in a wide range of fuels, Freon, oils, gases including NG, propane, SF6 and other chemicals along with the appropriate o-ring compound. Free epoxy samples can be requested by the customer to evaluate in their particular chemical requirements. PAVE-Seal 200 has passed the rigorous Factory Mutual Class 3600 chemical resistance requirements as detailed in the FM specification.

37. What is the PAVE-Seal epoxy Comparative Tracking Index or CTI used to measure the electrical breakdown (tracking) properties used for electrical safety assessment by Underwriters Laboratory?

The CTI value is used for the electrical safety assessment of electrical apparatus, as for instance carried out by Underwriters Laboratory. The minimum required creepage distances over an insulating material between electrically conducting parts in apparatus, especially between parts with a high voltage and parts that can be touched by human users, is dependent on the insulators CTI value. Also for internal distances in an apparatus by maintaining CTI based distances, the risk of fire is reduced. Performance Level Categories (PLC) were introduced to avoid excessive implied precision and bias. — CTI Test Results