Coaxial, EMI Shielded

MOST PAVE HERMETIC SEALS ARE BI-DIRECTIONAL SEALS FOR VACUUM OR PRESSURE.

Versions available include BNC, SMA, SHV, MHV, N and Triaxial with floating or grounded shields for pressure or vacuum uses. In addition, any type of coaxial or shielded cables can be hermetically sealed in almost any combination or length. Multi-pin coaxial PAVE-Mate connectors are also available up to 29 shielded contacts.

Coaxial RF connector versions are available for up to 40 GHz or 100 GHz use. SMA Ka-band or 1.0mm types. Typical impedance control is +-10% of the nominal impedance value for the type connector selected unless a non-constant impedance connector type. Any special electrical requirements such as VSWR, insertion loss, RF leakage, TDR testing or tight impedance control should be first discussed with a PAVE sales engineer before ordering.

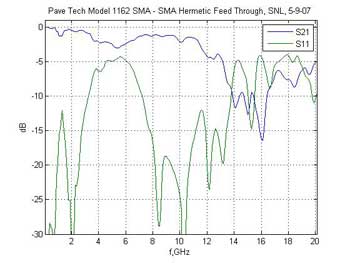

Please see the below chart of the plot of transmission and reflection coefficient that measured the full 2-port S-parameter data on a Sandia National Lab network analyzer

Downloads Serno 336851-033 Data Micro Coaxial Cable Seal

Technical Data

Seal Integrity PAVE-Seal® PAVE-Mate®

PAVE-Optic-SealTM PAVE-Flex®

While all PAVE products will comply with helium leak rating from <10-6 cc/sec to 10-9 cc/sec (air equivalent) depending upon design, PAVE also uses more cost effective air bubble in fluid leak testing typically at 80 psi (5 bar). Special high pressure testing up to 10 k psi (600 bar) is also available.

HERMETIC EPOXY TEMPERATURE RATING

(Epoxy is proprietary and not sold separately)

PAVE Wire Seal® 150 -40° to 150° C

PAVE Wire Seal® 200 -60° to 200° C

PAVE Wire Seal® 200FR UL94V-O flame retardant

Toxicity Ratink K (NASA MAPTIS

Odor Rating A

Thermal Vacuum Stability Rating A

Flammability Rating X

FM Class 3600, EExd II 90° C TI

SPECIFICATIONS

Dielectric Strength >17.4 kV/mm

Dielectric Constant 5.3@ 1 Mhz

Volume Resisivity @ 125° C1x1015 Ohm-cm

Dissipation Factor 0.03 @ 1 Mhz

Hardness, Shore D 96

Low Vacuum Outgassing:

TML 0.25%

CVCM 0.01%

High Fungus Resistance MIL-STD–454J/4

Specific Gravity @ 25° C 2.3

Compressive Strength >948 kg/cm2

Compressive Modules 7.7×104 kg/cm2

Tensile Strength >470 kg/cm2

Water Absorption (24 hours) 0.03%

The PAVE-Seal® epoxy is impervious to most oils, solvents, fuels, freons, gases, etc. Epoxy samples are available upon request for customer’s evaluation for any specific chemical compatibility.

Any type or size of wire or cable may be specified including coaxial cables, thermocouple wire pairs, high voltage wires, fiber optic cable, flat cables, etc. for length.

NO DETECTABLE LEAKAGE THRU CONDUCTOR OR INSULATION.

| Wire Conductor Gage (AWG) | O.D. | Amperage Rating | Nominal Insulation Overall | Nominal Insulation Diameter (O.D.) |

|---|---|---|---|---|

| 30 | 0.30 mm | 2 | .03 | 0.8 mm |

| 28 | 0.40 | 2 | .04 | 1.0 |

| 26 | 0.50 | 3 | .05 | 1.3 |

| 24 | 0.60 | 3 | .06 | 1.5 |

| 22 | 0.78 | 4 | .06 | 1.5 |

| 20 | 0.90 | 6 | .07 | 1.9 |

| 18 | 1.21 | 8 | .08 | 2.0 |

| 16 | 1.50 | 10 | .09 | 2.3 |

| 14 | 1.85 | 18 | .11 | 2.8 |

| 12 | 2.4 | 25 | .12 | 3.0 |

| 10 | 2.94 | 40 | .21 | 5.3 |

| 6 | 4.67 | 80 | .26 | 6.6 |